Breaking Through Barriers, Igniting the Light of Ultra-Purity: Zhongding Hengsheng Supports Winery Cold & Electric in Achieving a Major Leap in China's Helium Extraction Technology

Publishdate:2025-08-29 Source: Views:54

In an era of rapid technological advancement, the autonomous control of strategic resources is undeniably critical for national development. Recently, a piece of encouraging news emerged: the low-temperature purification and denitrogenation unit independently developed by Anhui Winery Cold & Electric Technology Co., Ltd. passed engineering acceptance at the natural gas helium extraction project site in Yan'an, Shaanxi, producing helium gas with a purity of 99.99997% (6N9 grade). This achievement marks a qualitative leap for China in the field of low-abundance natural gas helium extraction, transitioning from catching up to leading the way. Behind this breakthrough, Zhongding Hengsheng, as a strategic partner of Winery Cold & Electric, provided critical support with four high-performance diaphragm compressors as core components of the process, playing a vital role in the joint effort to overcome technological barriers.

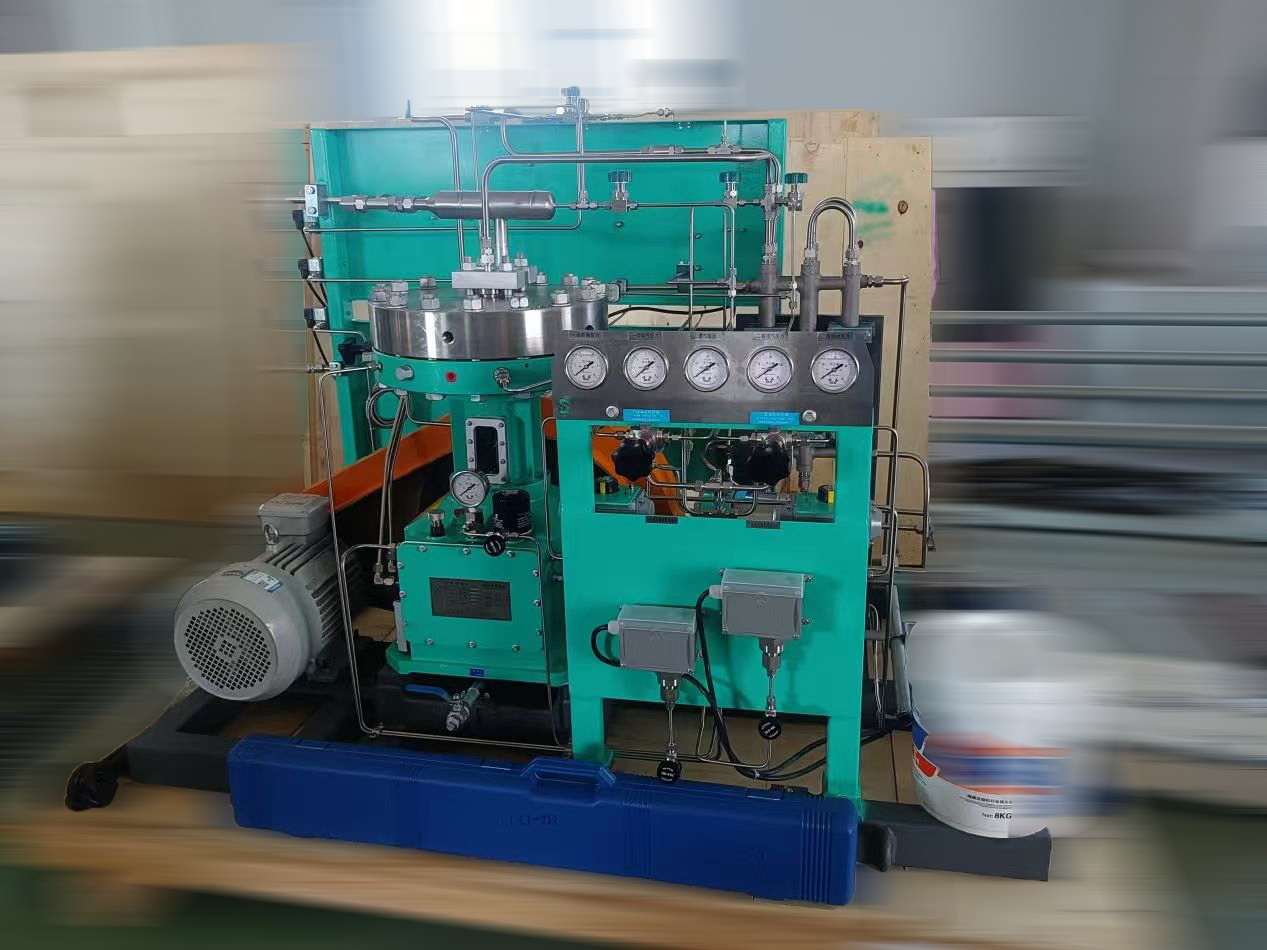

Image source: Winery Cold & Electric

Helium, as a national strategic resource, holds an irreplaceable position in fields such as aerospace, semiconductor manufacturing, and cutting-edge scientific research. Previously, domestically produced helium struggled to achieve purity levels above 99.9999% (6N grade), failing to meet high-end demands. As a result, 90% of the high-purity helium required for high-end manufacturing relied on imports. Western countries, led by the United States, have built helium barriers through technological blockades and resource control, exacerbating the situation.

Faced with this "chokehold" dilemma, domestic companies chose to collaborate to break through. A domestically developed research team pioneered a "combined method" helium extraction process system, which innovatively integrates four core technologies—dehydrogenation, membrane separation, pressure swing adsorption, and low-temperature purification—into a deeply coupled, fully optimized, and precisely controlled system.

Image source: Winery Cold & Electric

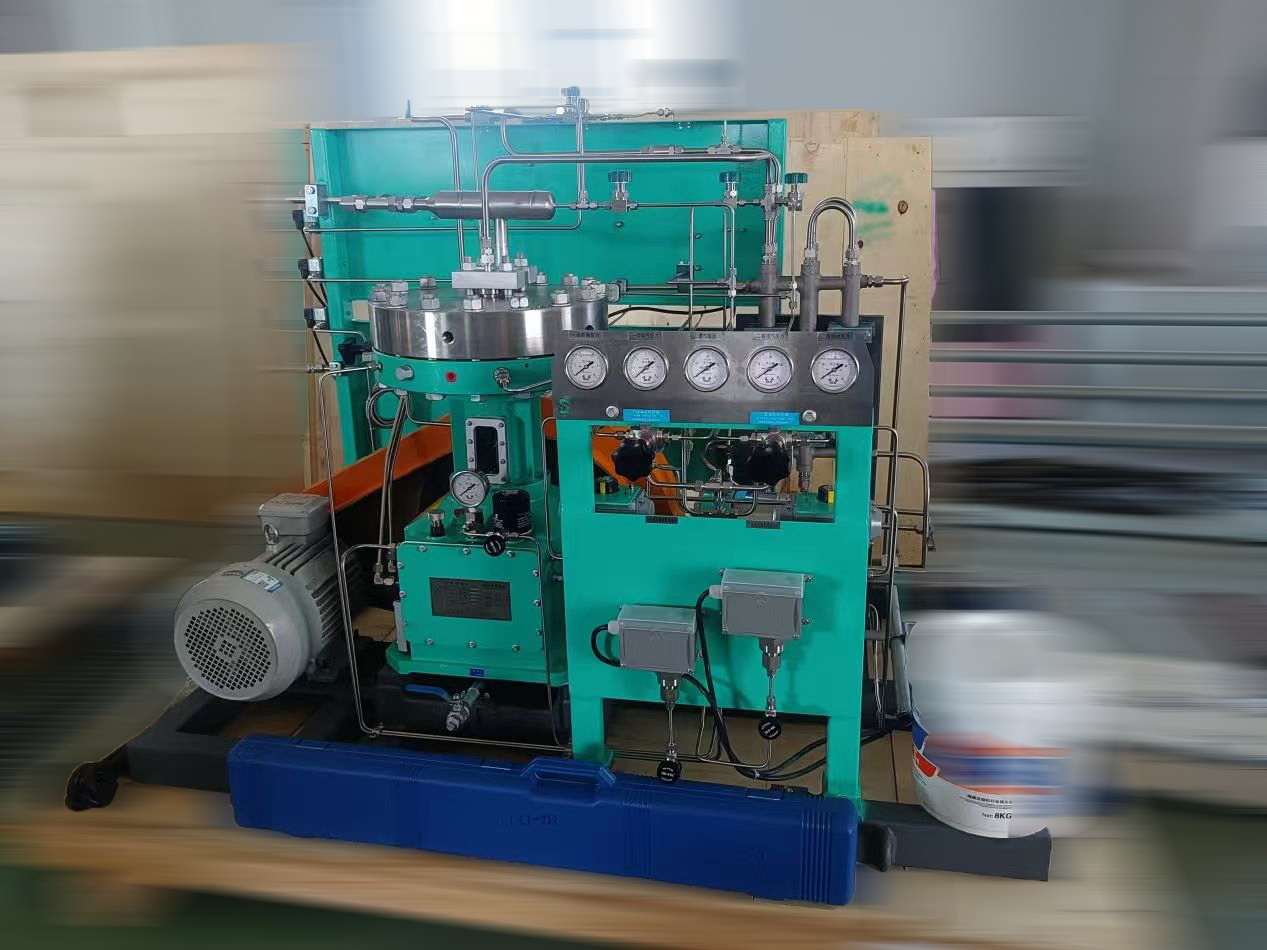

In the Yan'an helium extraction project, the four diaphragm compressors provided by Zhongding Hengsheng served as the "power heart" of the helium purification process. Due to helium's high permeability and chemical inertness, conventional compression equipment is prone to leakage and contamination issues. However, Zhongding Hengsheng's diaphragm compressors, featuring special sealing structures, achieve zero-leakage compression, ensuring helium purity remains uncompromised. Their precise pressure control technology perfectly meets the pressure requirements at different stages of the helium extraction process, providing a stable gas source for subsequent steps.

Notably, the strategic collaboration between Winery Cold & Electric and Zhongding Hengsheng offers a model for domestic equipment breakthroughs. Throughout the project's development, the technical teams of both companies worked closely together. Zhongding Hengsheng made several customized improvements to the compressors to meet Winery Cold & Electric's unique process requirements, ensuring perfect compatibility with the new "combined method" helium extraction system and creating internationally competitive equipment. This "process-equipment" collaborative innovation mechanism effectively addresses "chokehold" technological challenges, demonstrating that domestic companies can break through technological blockades and achieve leapfrog development through industrial chain synergy.

At the crossroads of global technological competition, this breakthrough is not only a victory for Chinese manufacturing but also a triumph for independent innovation systems. When 6N9-grade helium flows through the metal pipes of the low-temperature purification unit, it carries not only the autonomous lifeline of strategic resources but also the spiritual symbol of Chinese scientists and engineers breaking through blockades and achieving self-reliance. This silent technological revolution is reshaping the global competition landscape for strategic resources.

In an era of rapid technological advancement, the autonomous control of strategic resources is undeniably critical for national development. Recently, a piece of encouraging news emerged: the low-temperature purification and denitrogenation unit independently developed by Anhui Winery Cold & Electric Technology Co., Ltd. passed engineering acceptance at the natural gas helium extraction project site in Yan'an, Shaanxi, producing helium gas with a purity of 99.99997% (6N9 grade). This achievement marks a qualitative leap for China in the field of low-abundance natural gas helium extraction, transitioning from catching up to leading the way. Behind this breakthrough, Zhongding Hengsheng, as a strategic partner of Winery Cold & Electric, provided critical support with four high-performance diaphragm compressors as core components of the process, playing a vital role in the joint effort to overcome technological barriers.

Image source: Winery Cold & Electric

Helium, as a national strategic resource, holds an irreplaceable position in fields such as aerospace, semiconductor manufacturing, and cutting-edge scientific research. Previously, domestically produced helium struggled to achieve purity levels above 99.9999% (6N grade), failing to meet high-end demands. As a result, 90% of the high-purity helium required for high-end manufacturing relied on imports. Western countries, led by the United States, have built helium barriers through technological blockades and resource control, exacerbating the situation.

Faced with this "chokehold" dilemma, domestic companies chose to collaborate to break through. A domestically developed research team pioneered a "combined method" helium extraction process system, which innovatively integrates four core technologies—dehydrogenation, membrane separation, pressure swing adsorption, and low-temperature purification—into a deeply coupled, fully optimized, and precisely controlled system.

Image source: Winery Cold & Electric

In the Yan'an helium extraction project, the four diaphragm compressors provided by Zhongding Hengsheng served as the "power heart" of the helium purification process. Due to helium's high permeability and chemical inertness, conventional compression equipment is prone to leakage and contamination issues. However, Zhongding Hengsheng's diaphragm compressors, featuring special sealing structures, achieve zero-leakage compression, ensuring helium purity remains uncompromised. Their precise pressure control technology perfectly meets the pressure requirements at different stages of the helium extraction process, providing a stable gas source for subsequent steps.

Notably, the strategic collaboration between Winery Cold & Electric and Zhongding Hengsheng offers a model for domestic equipment breakthroughs. Throughout the project's development, the technical teams of both companies worked closely together. Zhongding Hengsheng made several customized improvements to the compressors to meet Winery Cold & Electric's unique process requirements, ensuring perfect compatibility with the new "combined method" helium extraction system and creating internationally competitive equipment. This "process-equipment" collaborative innovation mechanism effectively addresses "chokehold" technological challenges, demonstrating that domestic companies can break through technological blockades and achieve leapfrog development through industrial chain synergy.

At the crossroads of global technological competition, this breakthrough is not only a victory for Chinese manufacturing but also a triumph for independent innovation systems. When 6N9-grade helium flows through the metal pipes of the low-temperature purification unit, it carries not only the autonomous lifeline of strategic resources but also the spiritual symbol of Chinese scientists and engineers breaking through blockades and achieving self-reliance. This silent technological revolution is reshaping the global competition landscape for strategic resources.