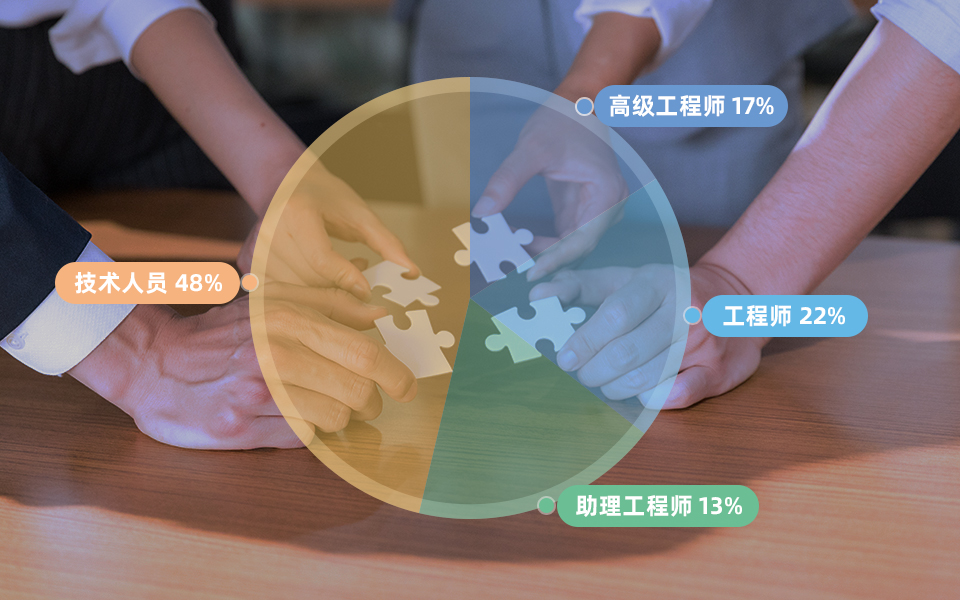

The company attaches importance to technological research and development and continuous innovation. It starts from multiple aspects such as market demand orientation, internal development drive, research and development, team incentives and constraints, and establishes a continuous innovation mechanism for technological research and development that meets the requirements of industry development and the company's own characteristics.

The company has set up an R&D team to carry out R&D activities, constantly optimize the R&D system and attract high-level R&D talents. On the one hand, it mobilizes enthusiasm through various incentive methods such as project rewards and job promotions. On the other hand, through a good career development platform and incentive measures, it attracts R&D personnel with scientific research capabilities and rich industry experience to join the company and expand the R&D strength.

In the future, the company will continuously enhance its attraction to R&D talents, establish and improve a talent selection, cultivation, assessment and incentive mechanism that suits the characteristics of the company, and constantly improve the R&D capabilities of the R&D team.