According to different preparation methods and application fields, industrial gases can be divided into bulk gases and special gases. Special gases can be divided into high-purity gases, standard gases and electronic special gases. The downstream applications of electronic special gases are extensive, including integrated circuits, display panels, photovoltaics, LEDs, etc. The main production processes of special gases include gas synthesis, gas purification, gas blending, gas cylinder treatment, gas filling, etc. Gas filling refers to filling gas into pressure vessels such as gas cylinders through pressure difference. The improvement of the purity of special gases is the core technical bottleneck. Integrated circuits have strict requirements for the purity of electronic special gases. Because in the chip processing process, even trace impurities may cause major defects in the product. The higher the purity of special gases, the higher the yield and the better the performance of the product. With the continuous development of IC chip manufacturing process technology, the production accuracy of products is getting higher and higher, and higher purity requirements are also put forward for electronic special gases used in integrated circuit manufacturing.

Petrochemical industry is an important part of the chemical industry and plays an important role in the development of the national economy. It is one of the pillar industrial sectors in our country. Petrochemical industry refers to the use of petroleum and natural gas as raw materials. The first step in production is the cracking of raw oil and gas (such as propane, gasoline, diesel, etc.). Diaphragm compressors can be used to compress various petrochemical raw materials, such as hydrogen, nitrogen, oxygen, carbon dioxide, etc., as well as for gas transportation and pressure control in the production process.

The earliest hydrogen refueling station can perhaps be traced back to the hydrogen refueling station in Los Alamos, USA in the 1980s. At that time, the Los Alamos National Laboratory in the US built this station to verify the feasibility of liquid hydrogen as a fuel. Since then, more and more hydrogen refueling stations have been gradually built.

According to the latest data from the hydrogen energy industry research institution Xiangcheng Hui, as of the end of June 2024, 426 hydrogen refueling stations have been built in China, among which 19 new stations were added in the first half of 2024 alone.

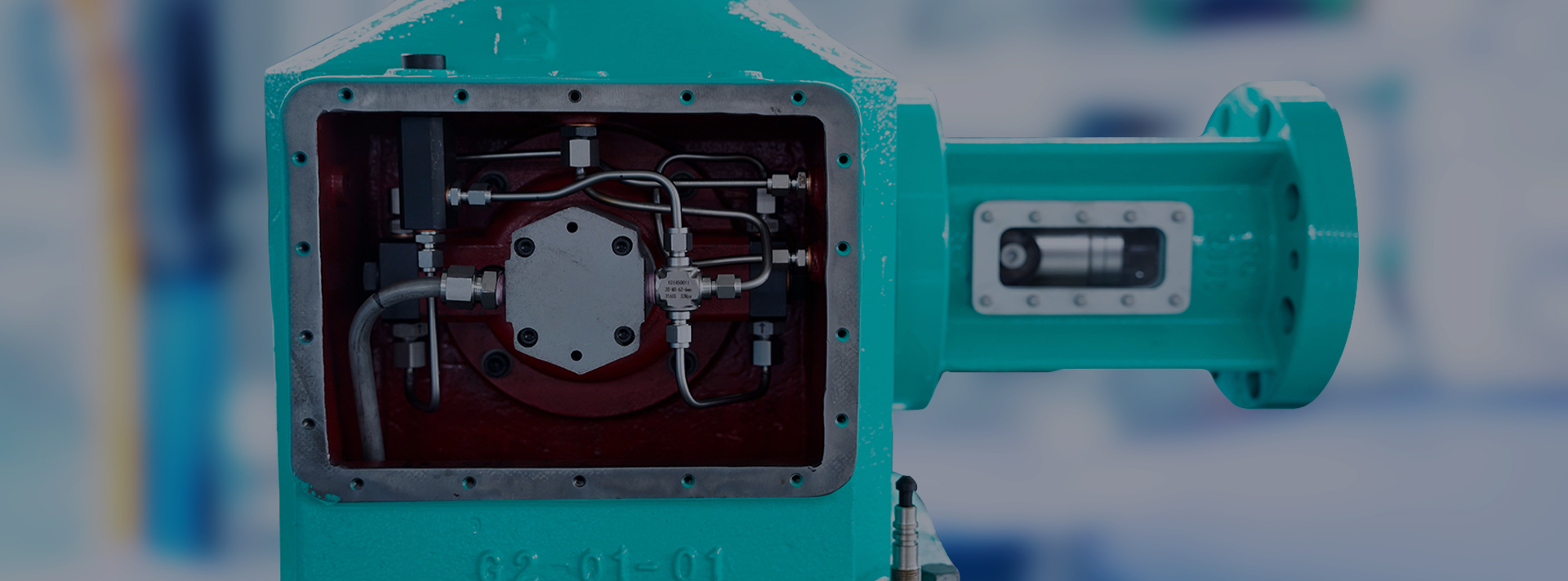

The development of the hydrogen energy industry is inseparable from technological innovation and the improvement of the industrial chain. At present, China has made significant progress in all aspects of hydrogen energy production, storage, transportation, and application. As an important equipment in each stage of hydrogen "production, storage, transportation, refueling, and application", the diaphragm compressor can compress gas with extremely high purity, which can generally reach a purity of 99.999%.

First, let's understand a concept. Fine chemicals. Chemicals with characteristics such as low investment, high rate of return, high profit margin, high added value, high knowledge intensity, and long patent period in small quantities and multiple varieties are called fine chemicals. The industry that produces fine chemicals is collectively called fine chemical industry. Fine chemical products in China include 11 product categories: pesticides; dyes; coatings (including paints and inks); pigments; reagents and high-purity substances; information chemicals (including chemicals that can receive electromagnetic waves such as photosensitive materials and magnetic materials); food and feed additives; adhesives; catalysts and various auxiliaries; (chemically produced by the chemical industry system) chemical drugs (bulk drugs) and daily-use chemicals; functional polymer materials in polymer polymers (including functional membranes, polarizing materials, etc.).

Military nuclear power plays an important role in national defense construction and involves the research, development and production of nuclear weapons. For example, atomic bombs, hydrogen bombs and nuclear submarines. Apart from military applications, military nuclear power also covers technologies for the peaceful use of nuclear energy, such as the construction and operation of nuclear power plants. Military nuclear power is not only related to the country's military security, but also an important force to promote the transformation of the national energy structure and economic development. Diaphragm compressors can be used to compress various gases and liquids in the production process of nuclear power and nuclear energy, such as helium, nitrogen, oxygen, etc., as well as for transportation and pressure control.

In the production and packaging processes, the food industry also requires the use of oil-free and pollution-free gases. Diaphragm compressors can provide the food industry with high-quality gas supply to ensure the safety and hygiene of food. They can also be used to compress various food and pharmaceutical raw materials, such as milk powder and pharmaceutical intermediates, as well as for gas transportation and pressure control in the production process.

The medical industry has a large demand for high-purity gases. Especially in the pharmaceutical manufacturing process, oil-free and pollution-free gases are needed. Diaphragm compressors can provide high-purity and pollution-free gas supply to meet the requirements of the pharmaceutical process.

Compressors used in ultra-high pressure test devices for scientific research, with a maximum pressure of 200 MPa, and compressors for pilot and small-scale tests in chemical plant devices. In the field of nanotechnology, diaphragm compressors can precisely compress and convey high-purity gases to support the preparation and research of nanomaterials and devices.