Cross-Border Symbiosis: The Inseparable Bond Between Chip Manufacturing and Diaphragm Compressors

Publishdate:2025-09-09 Source: Views:60

When it comes to chip manufacturing, people often think of core components like lithography machines and wafers, but few notice that diaphragm compressors also play a crucial role in safeguarding key steps of chip production. Recently, Liu Juan, Vice General Manager of Zhongding Hengsheng Gas Equipment (Wuhu) Co., Ltd. and Head of the Marketing Center, appeared on the "Chip Secrets Revealed" program, unveiling the mystery of this critical technology to the audience—it acts as the "gas steward" of chip manufacturing, supporting the stable operation of the semiconductor industry with high precision and reliability.

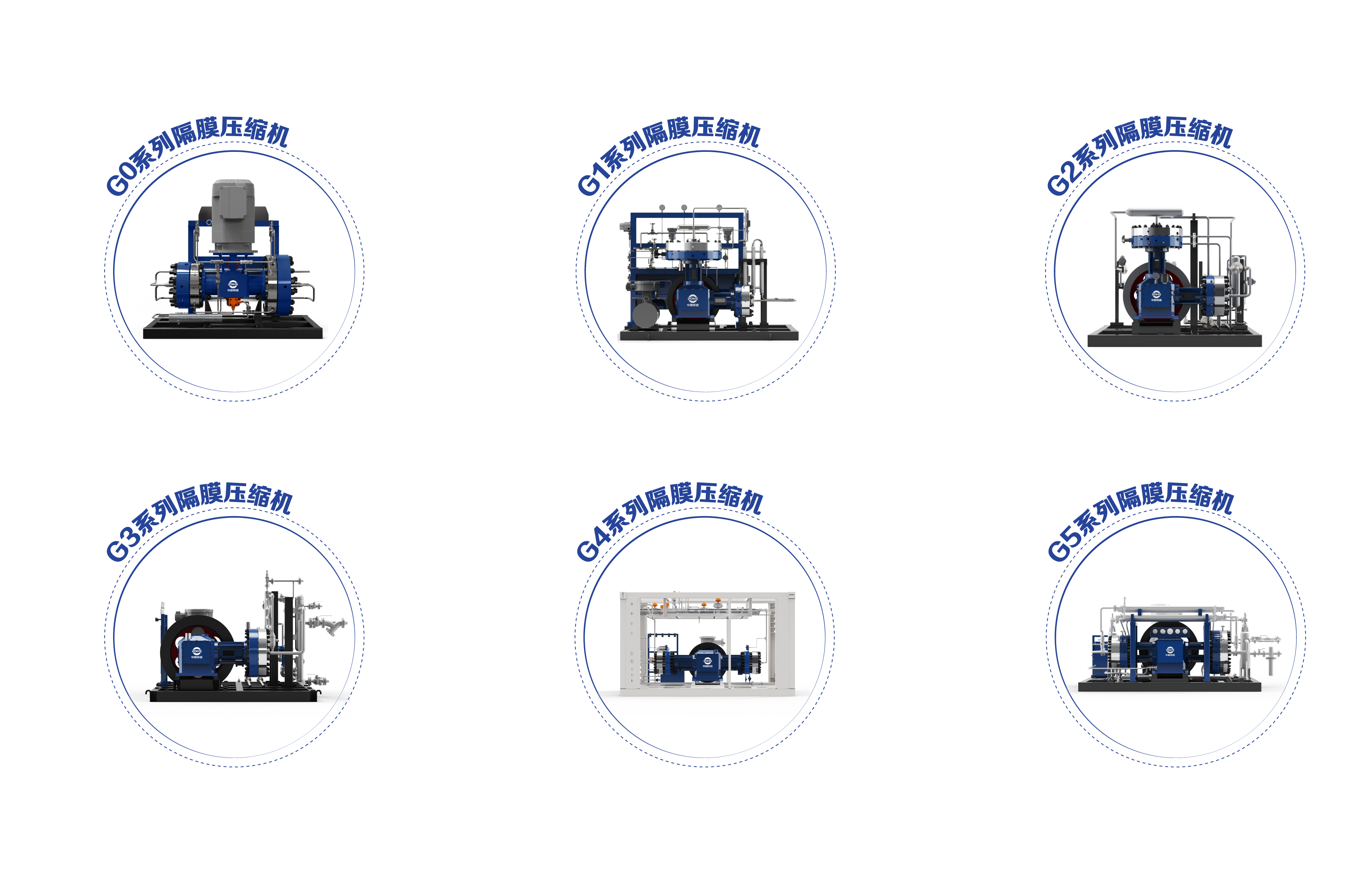

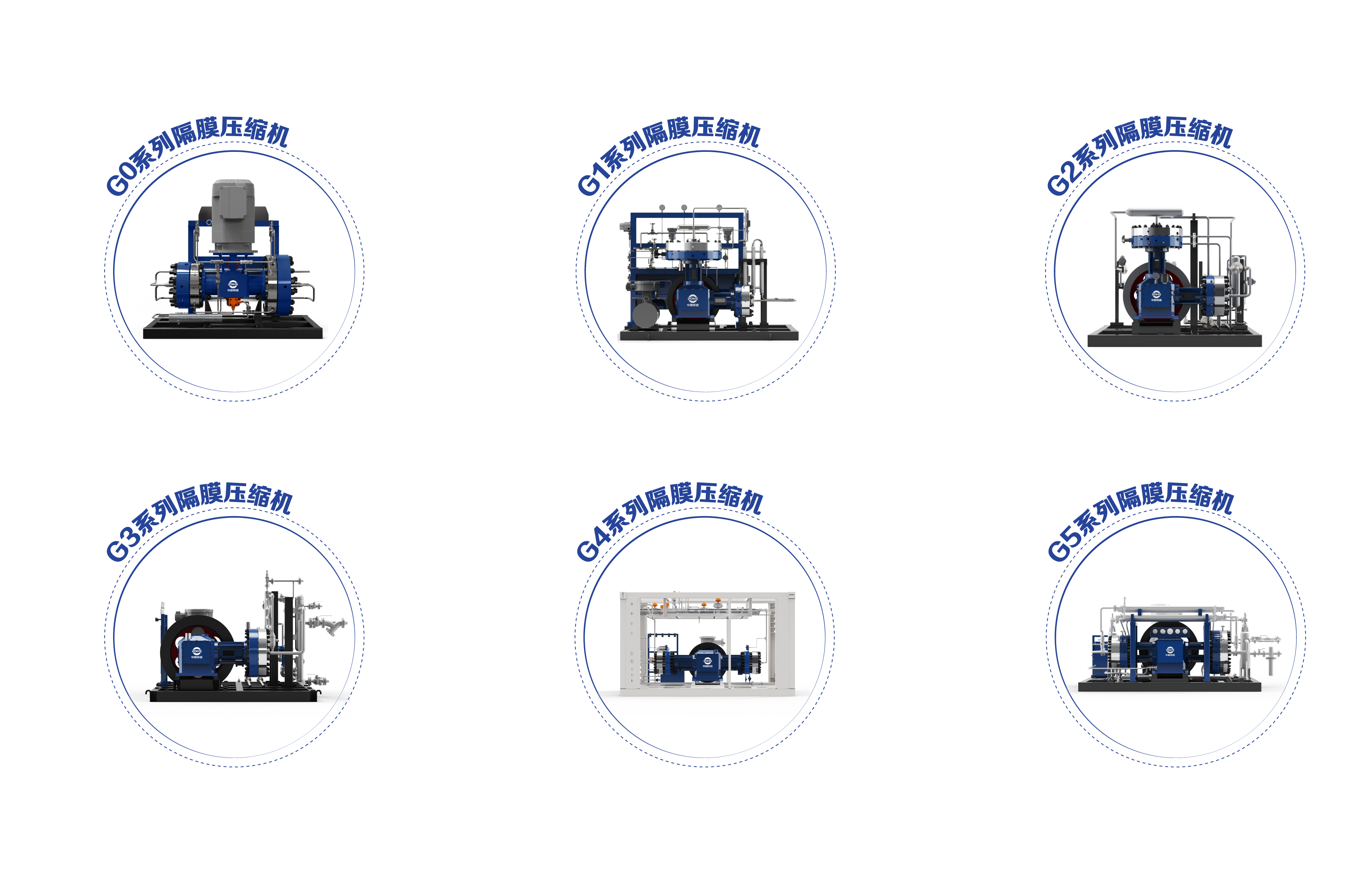

The chip manufacturing process requires a large amount of ultra-high-purity specialty gases, such as helium, argon, hydrogen, and nitrogen, which are widely used in key processes like etching, deposition, lithography, and ion implantation. The purity and stability of gas delivery directly determine the yield and performance of chip products, and diaphragm compressors serve as the "core power" enabling this process.

Specifically, the services provided by diaphragm compressors to the chip industry focus on "specialty gas pressurization and delivery." Ms. Liu mentioned that specialty gases used in chip manufacturing are typically stored at low pressure, while production equipment requires high-pressure gas to function properly. This necessitates compressors to perform "pressure boost operations." However, conventional compressors are prone to gas leakage and contamination issues. If impurities mix with the specialty gases, it could lead to chip defects or even scrapping. Compared to traditional compressors, diaphragm compressors employ a unique metal diaphragm isolation structure, ensuring that the gas never comes into contact with lubricating oil or metal components, thereby maintaining extremely high cleanliness during compression.

In addition to "contamination prevention and high precision," diaphragm compressors also provide "continuous and stable power support" for chip production. Ms. Liu explained that through technological iterations, Zhongding Hengsheng has achieved highly efficient and stable operation of its equipment, meeting the demands of 24/7 uninterrupted production in chip factories. The chip manufacturing process is complex and continuous, and any interruption in gas supply could halt the production line, resulting in significant losses. By optimizing materials for core vulnerable components and enhancing the equipment's anti-interference capabilities, Zhongding Hengsheng's diaphragm compressors minimize failure rates, serving as a "reliable backbone" for chip factories.

It is worth noting that the technological breakthroughs of this "chip enabler" were achieved through a long and arduous journey. Ms. Liu recalled in the program that diaphragm compressor technology in China began in the 1950s and 1960s, with early production limited to small-scale devices. It was not until Luo Keqin, the founder of Zhongding Hengsheng, achieved a breakthrough in "equipment large-scaleization" and won the third prize of the China Machinery Industry Science and Technology Award that domestic equipment gradually caught up with international standards. Today, Zhongding Hengsheng's diaphragm compressors have replaced imported products and are being used by several major domestic gas companies, breaking the monopoly of foreign brands in this field.

This cross-border dialogue on "Chip Secrets Revealed" not only introduced diaphragm compressors to a wider audience but also highlighted a critical insight: the development of the chip industry relies on technological support from upstream and downstream niche sectors. From lithography machines to diaphragm compressors, every breakthrough by these "unsung heroes" contributes to the autonomous and controllable development of China's semiconductor industry.

When it comes to chip manufacturing, people often think of core components like lithography machines and wafers, but few notice that diaphragm compressors also play a crucial role in safeguarding key steps of chip production. Recently, Liu Juan, Vice General Manager of Zhongding Hengsheng Gas Equipment (Wuhu) Co., Ltd. and Head of the Marketing Center, appeared on the "Chip Secrets Revealed" program, unveiling the mystery of this critical technology to the audience—it acts as the "gas steward" of chip manufacturing, supporting the stable operation of the semiconductor industry with high precision and reliability.

The chip manufacturing process requires a large amount of ultra-high-purity specialty gases, such as helium, argon, hydrogen, and nitrogen, which are widely used in key processes like etching, deposition, lithography, and ion implantation. The purity and stability of gas delivery directly determine the yield and performance of chip products, and diaphragm compressors serve as the "core power" enabling this process.

Specifically, the services provided by diaphragm compressors to the chip industry focus on "specialty gas pressurization and delivery." Ms. Liu mentioned that specialty gases used in chip manufacturing are typically stored at low pressure, while production equipment requires high-pressure gas to function properly. This necessitates compressors to perform "pressure boost operations." However, conventional compressors are prone to gas leakage and contamination issues. If impurities mix with the specialty gases, it could lead to chip defects or even scrapping. Compared to traditional compressors, diaphragm compressors employ a unique metal diaphragm isolation structure, ensuring that the gas never comes into contact with lubricating oil or metal components, thereby maintaining extremely high cleanliness during compression.

In addition to "contamination prevention and high precision," diaphragm compressors also provide "continuous and stable power support" for chip production. Ms. Liu explained that through technological iterations, Zhongding Hengsheng has achieved highly efficient and stable operation of its equipment, meeting the demands of 24/7 uninterrupted production in chip factories. The chip manufacturing process is complex and continuous, and any interruption in gas supply could halt the production line, resulting in significant losses. By optimizing materials for core vulnerable components and enhancing the equipment's anti-interference capabilities, Zhongding Hengsheng's diaphragm compressors minimize failure rates, serving as a "reliable backbone" for chip factories.

It is worth noting that the technological breakthroughs of this "chip enabler" were achieved through a long and arduous journey. Ms. Liu recalled in the program that diaphragm compressor technology in China began in the 1950s and 1960s, with early production limited to small-scale devices. It was not until Luo Keqin, the founder of Zhongding Hengsheng, achieved a breakthrough in "equipment large-scaleization" and won the third prize of the China Machinery Industry Science and Technology Award that domestic equipment gradually caught up with international standards. Today, Zhongding Hengsheng's diaphragm compressors have replaced imported products and are being used by several major domestic gas companies, breaking the monopoly of foreign brands in this field.

This cross-border dialogue on "Chip Secrets Revealed" not only introduced diaphragm compressors to a wider audience but also highlighted a critical insight: the development of the chip industry relies on technological support from upstream and downstream niche sectors. From lithography machines to diaphragm compressors, every breakthrough by these "unsung heroes" contributes to the autonomous and controllable development of China's semiconductor industry.